Bottom loading arms are increasingly preferred by the Customers as these arms offer several

Benefits over the Top loading arms, such as:

![]() Safety to the operators.

Safety to the operators.

![]() Connection for filling can be made quickly.

Connection for filling can be made quickly.

![]() Filling is faster and number of compartments can be filled simultaneously.

Filling is faster and number of compartments can be filled simultaneously.

![]() Danger of generating static electricity is less.

Danger of generating static electricity is less.

![]() Vapor can be recovered fully.

Vapor can be recovered fully.

![]() Costly loading Platform can be eliminated.

Costly loading Platform can be eliminated.

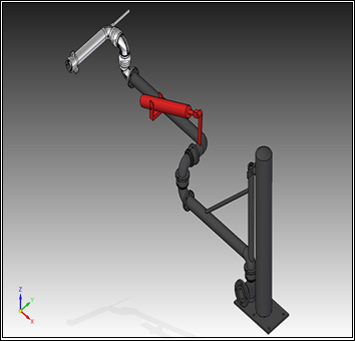

Our standard size is 4” with API Coupler as per API RP- 1004 which provides flow rate up to 2500 liters per minute. Available other sizes are 2”, 3” and 6” with various end fittings, such as loose flange with stub end, quick coupling, unions or other customer specified end fittings.

SPRING BALANCED BOTTOM HOSE LOADER :

This model offers several advantages, such as:

BOTTOM LOADING/ UNLOADING ARM :

This model offers several advantages, such as: