The critical component of a loading arm is Swivel Joint. Ferro Tube offers a wide range of swivel joints in terms of their size, type and MOC to meet the customers every requirement. Available sizes are 2”, 3”, 4” and 6”.

Ferro Tube swivel joints have double row of ball bearings. Each swivel joints are accurately CNC machined to highly close tolerances. Both the ball races are hardened suitably. Hence, the hardened, micro- finished and widespread row of ball bearing races provides increased load bearing capacity and also, long bearing life.

A grease nipple which accepts standard grease gun is provided between the ball races for periodic field greasing. Standard seals are Viton and other available seals are Buna- N, EPT, EPDM or as specified by the customers.

Standard swivel joint :

Split flange swivel joint :

Heavy duty split flange swivel joint :

Cast Aluminum Alloy swivel joint :

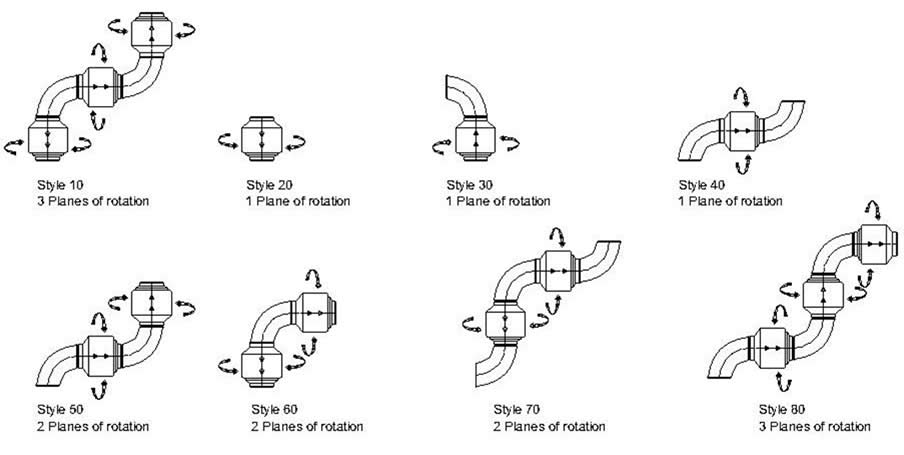

AVAILABLE STYLES FOR SWIVEL JOINTS :

Ferro Tube swivel joints are available in one, two or three planes of rotation for unlimited flexibility.

Various styles are illustrated below.

Each style can be supplied either in flanged ends (ANSI 150# or TTMA) or butt weld ends to suit customers every requirement. Standard combination of different metals, such as carbon steel, stainless steel or aluminum and seal materials, such as Buna-N, Viton, EPDM, EPT etc. virtually meets almost all technical parameters for the products to be handled.

Available sizes are 2”, 3”, 4” and 6”.