Top loading arms are available in many configurations, sizes and MOC as per customers’ requirements. Available sizes are 2”, 3”, 4” and 6”.

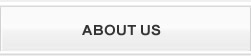

Standard Top loading arms are spring balanced either by a Torsion spring unit or a Compression spring unit. Loading arms can be supplied in Up-feed or Down-feed configurations with Left hand or Right hand combination to suit customers loading Platform.

In order to suit loading installation’s piping, loading arm’s inlet/ base flange is always WNRF, 150# as per ANSI B16.5. Other intermediate flanges are either TTMA or SORF, 150# as per ANSI B16.5.

Vacuum breaker and locking arrangements, such as Filling position lock and Parking position lock are provided as per customers’ requirements. Several additional components can also be provided with our loading arms which are ‘optional’. These are ball valves, T- Deflectors, Position sensor, Overspill Protection system, Vapor recovery attachment etc.

SHORT REACH LOADER/ SCISSOR ARM

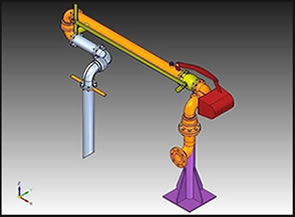

SUPPORTED LONG REACH LOADER:

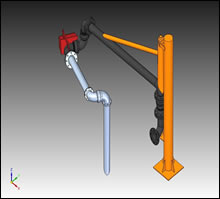

UNSUPPORTED LONG REACH LOADER:

LOADING ARM FOR SPECIAL APPLICATION:

Ferro Tube provides all technical assistance to their customers for design, manufacture and supply of loading arms for their special applications.

The above loading arm fitted with overspill protection system, is designed for loading highly hazardous and corrosive chemicals, namely diluted hydrochloric acid which is chemically non-resistant to carbon steel and stainless steel materials. The liquid flow passage of this model consists of inexpensive plastic pipes, fittings, hatch cover and flexible hoses. The metallic parts (rubber coated carbon steel) of this model are actually the carrying mechanism for plastic flow passage. However, the model offers all advantages of a conventional top loader, such as ease in handling and long maintenance free life.

Specially designed and manufactured for unloading highly hazardous and explosive chemical namely Concentrated Nitric acid (98%) from Tank Trucks. Flow passage here is constructed of pure aluminum materials (99.6%) of Gr. 1060 Temper-O. Supporting structure is made of SS materials.